Allen Bradley ControlLogix 5000 PLC and Automation Direct Logic 205 PLC Programming

Course Objective

This 6 days beginners to advance course is developed to give hand on practical experience and skills on PLCs Configuration, Programming and Maintenance. Application is opened to anyone desiring to become automation specialist.

Requirements

- Students are supposed to be familiar with Desktop/Laptop.

- No other prerequisites for this course, Because instructor will teach everything from scratch

Course Code: PLC001

Duration: 6 days; 8 hours per day

Course Fee: N420,000 ($800 USD)

Course Content

Day1 RSLogix5000 Software with ControlLogix5000 PLC

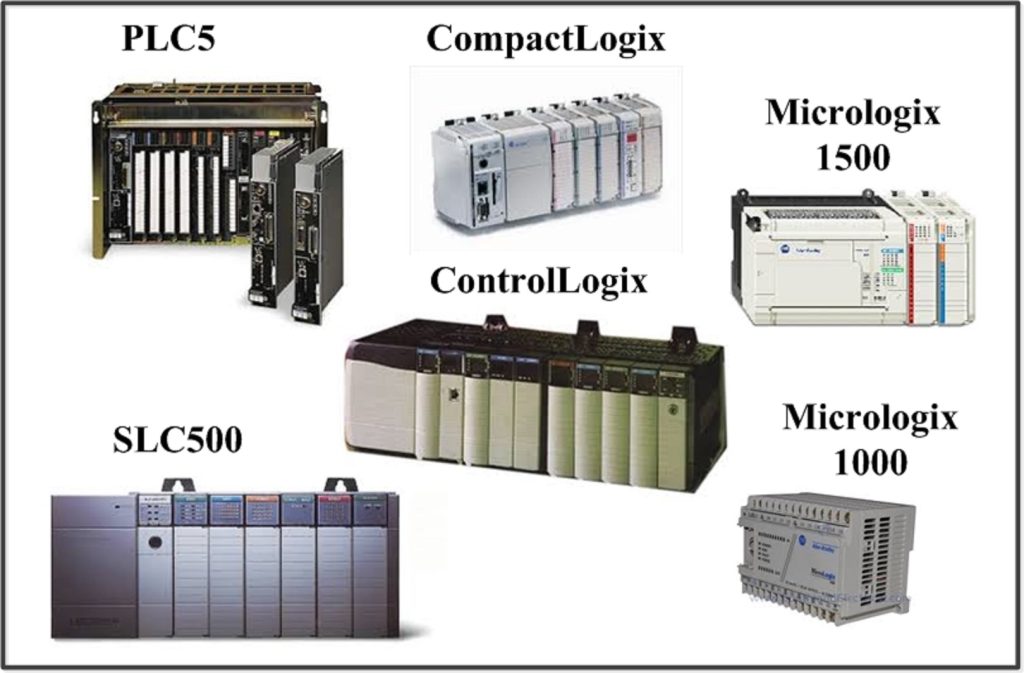

- Understanding Controllogix5000 system components / Hardware review

- Create a new Controller project and configure simulator I/O modules, manual and online discover method.

- Configure an Ethernet communications driver using RSLinks

- Connect your computer to a Network

- Upload/Download programs to a Contrologix5000 controller

- Understanding common data types

- Creating I/O Tags and Monitor data

- Organizing a RSLogix5000 project

- Creating new programs

- Adjust program schedules.

- Creating Period Task

- Creating Event Task

- Creating a new project/perform Offline and Online edits

- Understanding edit principles

- Program Basic Relay Instructions.

- Verify task, programs and routines

- Understanding and Modifying controller properties.

- Program and understand Sequencer Instructions and application.

- Configuring Controllers to Produce and Consume Data “Send data over the Ethernet”

- Configure Controllers to Produce and Consume Data “Across the backplane”

- Creating UDT User Defined Data Tags

- Programming Timer

- Programming Counter Instructions

- Application practice programming conveyor motors logic.

- Programming Understanding Compare Instructions

- Handling Expression in a Controllogix5000 system

- Programming/Understanding Math Instructions

Day2 RSLogix5000 Software with ControlLogix5000 PLC

- Creating a Periodic Task

- Creating an Event Task

- Programming /Understanding Data Handling Instructions

- Programming/Understanding Program Control Instructions

- Programming File Arithmetic and Move Instructions

- Program and understand MSG, “Message Instruction”. Share data over an Ethernet network.

- Program and understand Input – Output Instructions. GSV Get system Values SSV Set system values and IOT Immediate Output

- Developing an AOI “Add – On Instruction”

- Program and understand Special Instructions, FBC, DDT, DTR

- Programming File Arithmetic and Move Instructions

- Documenting and Searching Ladder Logic

- Troubleshooting / I/O Forcing / Bit Toggle / Trends

- How to Program Produced and Consumed Tags in RSLogix5000 to send bits over the Ethernet

- Programming File Search and Compare Instructions

- Program, Configure PID Instruction

- Configure an Analog I/O Module Voltage/Current and Engineering Units

- FBD Function Block Diagram, programming

- Understanding and recovering from Major Faults.

- Organizing Arrays, Single dimension, Double dimension and applications.

- Troubleshooting, Search and Cross Reference Ladder Logic

Day3 RSLogix5000 Software with ControlLogix5000 PLC

Develop, implement and program control loops for;

- Level control loop

- Motor control loop

- Pressure control

- Flow control loop

- Temperature control loop

- SIF control

- Class practice using real life equipment and instrumentations for individual candidate written programs.

- Troubleshooting and maintenance.

- Issue full training videos for all candidates

- Install free PLC programming software for all attendees’ laptops.

- Issue completion certificate

Day4 RSLogix5000 Software with ControlLogix5000 PLC

- Review, complete outstanding contents and practice more program examples of RSLogix5000 PLC

Day5 DirectLogic5 Software with Direct Logic 250 PLC

- PLC hardware

- Communication setup with PLC

- PLC Cycle scan

- Basic introduction to directlogix6 software features, instructions, monitoring the program

- DirectLogix6 advance programming

- Create new project

- Upload and download

Day6 DirectLogic5 Software with Direct Logic 250 PLC

- Develop, implement and program control loops for;

- Digital input and output

- Analog input and output

- Level control loop

- Motor control loop

- Pressure control

- Flow control loop

- Temperature control loop

- SIF control

Free PLCs programming software installation

- Guide trainees to download and install available free PLC software on their personal laptops for further practice

- Issue certificates