Siemens Simatic Manager with S7 315 PLC and Automation Direct Logic 250 PLC

Course Objective

This 6 days course is developed to give hand on practical experience and skills on PLCs Configuration, Programming and Maintenance. Application is opened to anyone desiring to become automation specialist.

Requirements

- Students are supposed to be familiar with Desktop/Laptop.

- No other prerequisites for this course, Because instructor will teach everything from scratch

Course Code: PLC005

Duration: 6 days; 9 hours per day

Course Fee: N355,750 ($680 USD)

Course Content

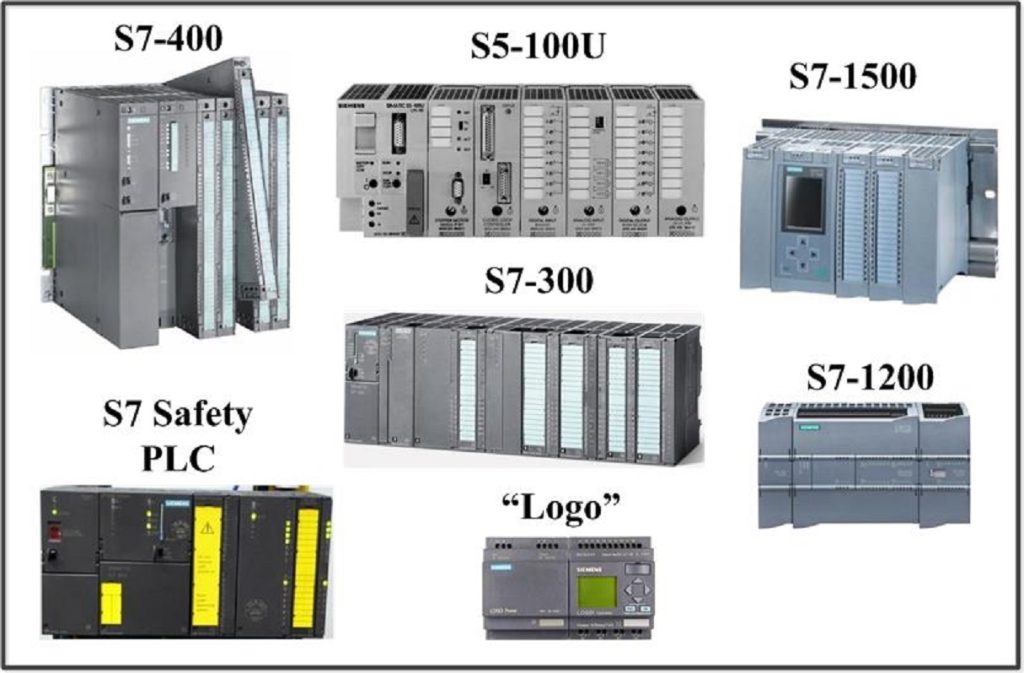

Day1: Siemens Simatic Manager and S7 315 CPU

- S7 300 hardware

- System Overview

- SImatic Manager Software Introduction

- Create a project

- Configure hardware

- Communication setup

- Project Management

- PG Interface

- Memory Introduction

- Memory Layout

- PLCSIM

- Downloading

- Watch Table

- PLC Tags

Day2: Siemens Simatic Manager and S7 315 CPU

- Instructions

- Numbering Systems

- Data Blocks

- Bit Level Instructions

- Timers

- Counters

- Reference Data

- Ladder logic

- Function Blocks

Day3: Siemens Simatic Manager and S7 315 CPU

- Analog IO

- Digital IO

- Compare Instructions

- FC and FB Blocks

- Trace Function

- PID programming

- Close loop programming

- Sequential programming

- Control loops Programming for Flow, Temperature, Level and Pressure

Day4: Siemens Simatic Manager and S7 315 CPU

- OB Blocks

- Configuring FieldBus Devices

- Forcing

- Troubleshooting

- Libraries

- Student sample programs review, download into PLC and upload from PLC

- Overview of other topics

- Student assignment

Day5 DirectLogic5 Software with Direct Logic 250 PLC

- PLC hardware

- Communication setup with PLC

- PLC Cycle scan

- Basic introduction to directlogix6 software features, instructions, monitoring the program

- DirectLogix6 advance programming

- Create new project

- Upload and download

Day6 DirectLogic5 Software with Direct Logic 250 PLC

- Develop, implement and program control loops for;

- Digital input and output

- Analog input and output

- Level control loop

- Motor control loop

- Pressure control

- Flow control loop

- Temperature control loop

- SIF control

Siemens Simatic Manager and S7 315 CPU and DirectLogic5 Software with Direct Logic 250 PLC

- Develop, implement and program control loops for;

- Digital input and output

- Analog input and output

- PID programming

- Wire sensors to PLC input channels

- Wire switches to PLC input channels

- Wire final control elements to PLC output channels

- Wire indicators to PLC output channels